-

-

Product name: PB6,PB5,PB6,PB8,PB10,PB12,PB14 cam clutch

-

-

Price: ASK

-

-

Post date: 2019-04-24

-

-

Stock Quantity:

-

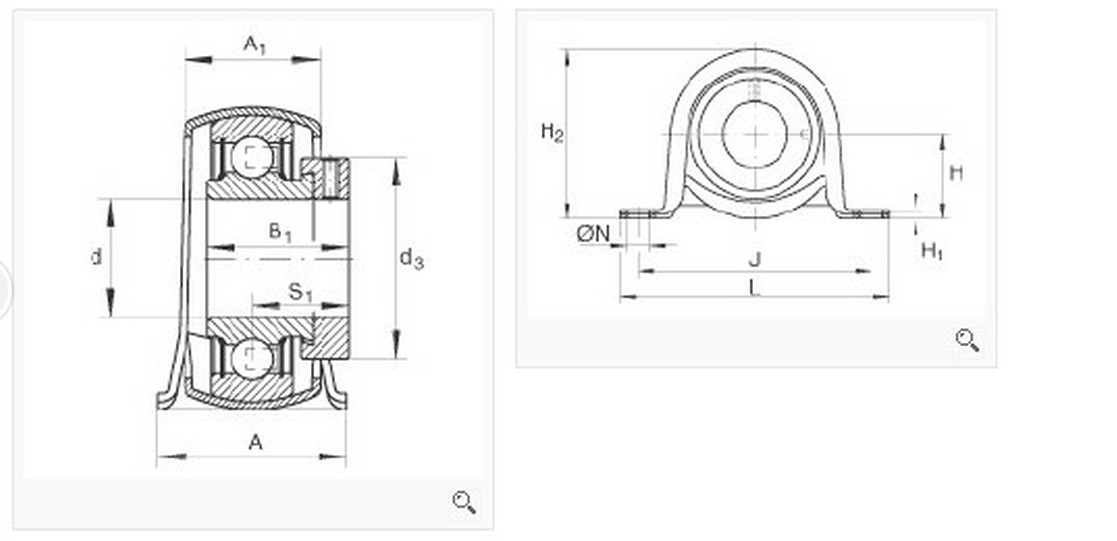

Pb series bearing is sprag -type one-way clutch, containing bearings. Required to use external grease and oil seals. This model is mainly used for ultra running speed clutch.

Clutch release bearing work, the clutch pedal force will be transmitted to the clutch release bearing. Clutch Bearing Clutch pressure plate toward the center, so that the pressure plate is pushed away from the clutch, the clutch plate and flywheel separation. When the clutch pedal is released, the pressure plate will spring pressure inside the pressure plate before the push, pressure to the clutch, the clutch plate and clutch bearing separation, and complete a cycle. PB clutch bearing model is complete, top quality and reasonable price.

Model

Torque Capacity

Max.Overrunning

Max.Indexing(cycle/min)

Stock Bore Size

A

B

Inner Race

Outer Pace

Dia(H7)

Keyway

PB3

29.4

1800

900

150

10

4×1.5

50

50

PB5

147

1800

900

150

16

5×2.0

70

60

PB6

382

1500

800

150

20

5×2.0

82

73

PB8

568

1200

650

150

25

7×3.0

85

83

PB10

843

1000

400

150

31.5

10×3.5

92

95

PB12

1530

800

300

150

40

10×3.5

100

113

PB14

2110

700

300

150

45

12×3.5

112

133

Model

C(h7)

D

E

F

G

Stock Bore Size

油栓 Lubrication

K

L

PB3

23

22

25

21

25.7

4×2.5

16

M6×P1.0

PB5

32

32

35

25

38.8

5×3.0

20

M6×P1.0

PB6

38

38

37

33

41.0

5×3.0

27

M6×P1.0

PB8

45

40

45

33

42.0

7×4.0

27

M6×P1.0

PB10

60

41

60

37

44.0

1O×4.5

28

M6×P1.0

PB12

65

50

66

37

52.6

1O×4.5

29

M6×P1.0

PB14

75

54

76

41

57.3

12×4.5

30

M6×P1.0

Features of one way clutch bearing:

A Cam Clutch mechanism integrated into a ball bearing cassette(#62 type)!

1)Compact Design

More efficient use of space with a one-way clutch and ball bearings all in a compact unit within the same dimensions as the bearings itself.

2)Reduced Cost

Keyless installation by just pressing the clutch into housings or onto shafts. There is no need to machine or harden the shaft as with conventional shell-type roller clutches.

3)Increased Torque Capacity

Many cam are installed between the bearings inner and outer race to allow a significantly increased torque capacity compared to shell-type roller clutches.

4)Full cam complement

The full complement of cams provide the maximum number of load transmitting members per given diameter, The result is a greater torque capacity size-for-size than other clutches.

5)Cam design

Precision formed cams made of a special alloy steel provide extra long wear and fatigue life.

6)High quality components

The clutch races are made of high-quality alloy steel with high surface hardness and core toughness. The races are precision groud, provide excellent concentricity and surface finish to obtain accurate cam rotation.

The major parts of the cam clutch are the cams, inner race, out race, springs and bearings. Each of these parts play an important role in the function of the cam clutch. All parts are made of carefully selected materials, have undergone appropriate heat treatment, and have passed strict quality control checks.

Applications of one way clutch bearing:

Air cleaning plants; Agricultural machines; Buchet elevators; Compressors; Conveyors; Cranes and hoists; Dry cleaning machinery; Duplicator equipment; Fish net machines; Heat-treatment furnaces; Induced draft fans; Multi-states conveyors; Packaging machinery; Printing machinery; Pumps; Punch presses and feeders; Power plants; Refinery equipment; Speed reducers; Standby power units; Textile looms; Two-speed grinders; Two-speed shiftovers; Washing machines; Wire winding machinery.